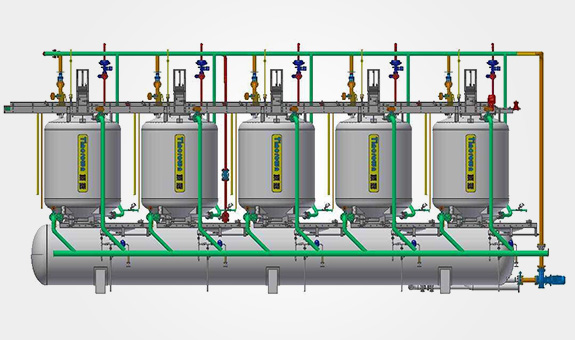

Continuous multiple towers sterilizer

The vertical sterilization kettle is suitable for the small pot shape in the three-piece pot, which is mainly based on the protection of the product shape

Product introduction and technical parameters

This equipment is a kind of continuous high temperature sterilization device which we newly developed, the most outstanding feature of this equipment is:

1.Supermatic.The products are installed into the special-made cage which is fixed on the cycle running chains , Chain drives the cage with full of products continuously uninterrupted to unload and load products and enters into the sterilizer ,heating, heat preservation, cooling,…… until completes the entire process of sterilization, like this continuous cycle process, can realize serial production . It could reduce the needs of sterilization process operators amount, thereby reduce the labor intensity in the sterilization operation process.

2.Energy conversation. On account of the continuous production, compared with the ordinary sterilizer, There are two biggest advantages of the energy saving are: one is maximum to reduce the amount of the heat energy which are produced from the steels of sterilizer tanks and cages when they are in the each sterilization process of repeated heating and cooling , The other advantage is maximum to recycle the machine itself heat after sterilization .(For example, this part of the waste heat energy will be used for sterilization products heating; used for raw materials of products preheating ; used for the others materials heating, etc). If all the measures are in place, the heat energy can be recycled by more than 60%.

3.In view of the heat energy of the sterilization products are maximum to be recycled in the process of sterilization technology, compared with the existing ordinary sterilizer, it can reduce the consumption of cooling water and the costs of cooling water treatment.

4.The entrance area of continuous multiple towers sterilizer can be placed in the nearest location of the packaging machine(such as filling and sealing equipment ) ,so it can be sterilized in the shortest time after completed the products packaging process. This feature is can shorten the waiting time before the sterilization , reduce the requirement of the workshop environment.

On the other hand,It can make all the products have the same waiting time from packaging to sterilization , create the favorable conditions for improving the quality of product sterilization technology.

5.In continuous multiple towers sterilizer, all the products go through each sterilization in accordance with the same path (preheating temperature-raising, heat preservation, sterilization, cooling, etc.).

So the product sterilization technology effect are almost the same (In theory, it will not be existed the specifications which is we usually emphasize the heat distribution in the sterilizer).

Comprehensive the above characteristics, we believe that the continuous multiple towers sterilizer will bring a revolutionary change in the existing food sterilization technology field, it can take the product sterilization quality up a notch and bring huge economic benefits for the food enterprises.

Scope of application: Vertical sterilizer is the most adapted to the small three-piece cans, which is mainly based on the protection of product appearance. And for meeting the product sterilization technology requirements, only the static sterilization technology can be adapted to the vertical sterilizer.

Cans products sterilization technological process

1.The sterilizer will be injected a certain height of hot water before loading the cans in it. The water temperature is equal to the initial temperature of food, There are two purposes for the hot water injection. One is the reason for the sterilizer is the no basket structure.Cans fall into the water from above mouth of the sterilizer, buffer dropping can protect the cans. The other reason is for doesn’t make the sterilization temperature reduce too much before the sterilization. The hot water will be played the role of buffer when the cans fall into the sterilizer. Cans feeding while water overflowing .

When the sterilizer completely loaded the stipulated number of cans products, closed the tank lid, filled with hot water. The filled hot water can completely discharge the air out of the sterilizer. (if don’t fill with water, it will need to use steam to blow the air in the upper sterilizer out of the tank .)

2.When the hot water inside the sterilizer is discharged to empty, continue to heat up to the setting temperature to sterilize.

3.It is supposed to do pressure maintaining and products cooling instantly after completed the sterilization. And then open the upper overflow pipe until the cooling ended. At last turn off all the valves.

4.Opening the tank Automatically, let the water inject into the tank as a buffer, because the tank door is doused into the water, it can make the tank form a vacuum state instantly. It can guarantee the cans to unload into the tank slowly.